Quality Assurance

We operate rigorous quality assurance systems across our global network, giving procurement teams confidence in every component and assembly we deliver.

Standards and Systems

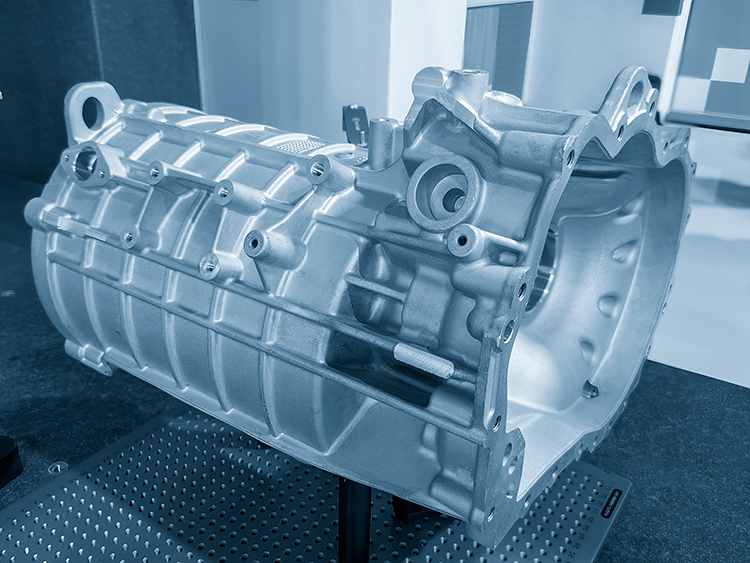

Sigma’s quality systems are built around recognised international standards, including IATF 16949 for automotive, ISO 9001 for general quality management, and AS9100 where applicable for aerospace and other regulated sectors. These frameworks support robust process control, traceability, and continuous improvement across design, manufacture, and final inspection.

Our inspection capabilities include dimensional and surface testing, metallurgical analysis, and precision measurement tools such as CMMs, ensuring every part meets specification and performance expectations before release.

Quality and Local Oversight

Quality at Sigma extends beyond our own facilities. We vet and qualify all trusted supply chain partners with documented assessments and performance evaluations. Our quality teams are present on the ground at key partner locations to monitor processes, support improvements, and ensure consistent adherence to standards throughout production.

With this proactive approach to supplier quality management, we minimise risk and help procurement teams rely on a consistent level of performance, regardless of where components are manufactured.

Talk to us

Contact Sigma to explore how our quality assurance systems and supply chain oversight can support your programme requirements.