Additive Manufacture

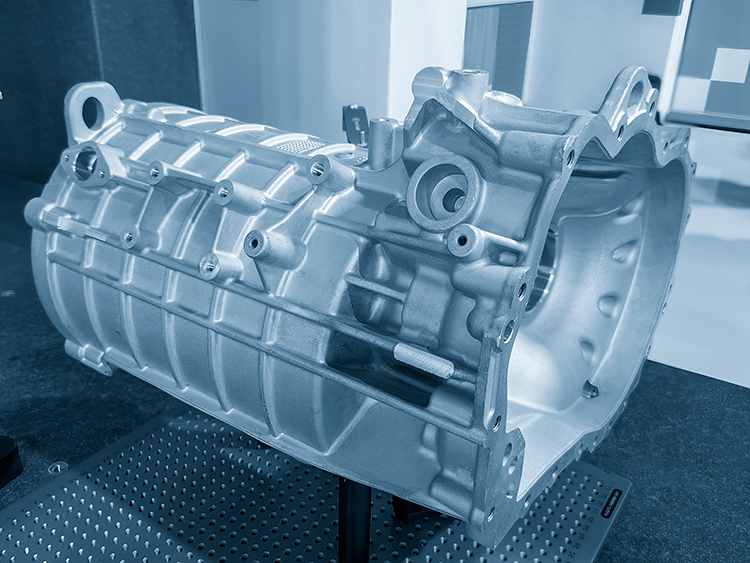

We work with advanced additive manufacturing partners to provide 3D printed components and prototypes, enabling rapid development, design flexibility, and customised parts where traditional methods are less efficient.

Design Freedom and Rapid Iteration

Additive manufacturing enables the production of complex geometries and internal features that are difficult or costly to achieve using traditional methods. This makes it particularly valuable during early design and prototyping, allowing faster iteration and reduced time to market.

Working with trusted partners, Sigma integrates additive manufacturing into wider production programmes, supporting prototyping, cast part development, and hybrid workflows that combine printed components with conventional finishing.

On Demand Manufacturing

Additive manufacturing can complement traditional production by enabling on-demand manufacture of low volume or bespoke components, helping reduce lead times and minimise inventory while supporting design changes.

By working with trusted additive partners and our global manufacturing network, Sigma can incorporate printed parts into complete manufacturing solutions, giving procurement teams greater flexibility and simpler supply chain management.

Talk to us

Contact Sigma to explore how additive manufacturing can support your prototyping needs, complex component designs, and flexible production strategies.